The Internet of Things is one of the biggest names in the industrial sector today. The Industrial IoT, also known as Industry 4.0, holds the key to unlocking great reductions in downtimes, new business models, and a better overall customer experience.

To achieve maximum productivity, provide customers with quality products and services within record time, and grow exponentially in a short period of time, modern manufacturing businesses are turning towards digital transformation with IoT.

So, what is IoT in manufacturing and how can it help various companies successfully implement digital transformation strategies?

Industry 4.0 and IIoT

The Internet of Things can be described as a system of devices (or ‘things’) connected to and communicating via a common network. The application of this technology goes beyond personal computers and smartphones and includes such devices as refrigerators, tractors, and clocks, which were not originally designed with such connectivity in mind.

IIoT is the subdivision of IoT that deals with streamlining industrial workflows and finding solutions to Industry 4.0 challenges. The list of those includes growing customer expectations, high demand for customization, complex supply chain management, and a bigger number of devices.

Businesses that opt for IIoT implementation equip every production stage with advanced devices and specialized software. This makes the entire process more transparent and effective than ever before.

What are the benefits of the Internet of Things in manufacturing?

In the current era of Industry 4.0, it is important for enterprises to be agile and react promptly to changes in supply and demand. IoT in manufacturing helps enterprises to perform this transformation in the best way and boost the role of data in critical decision-making.

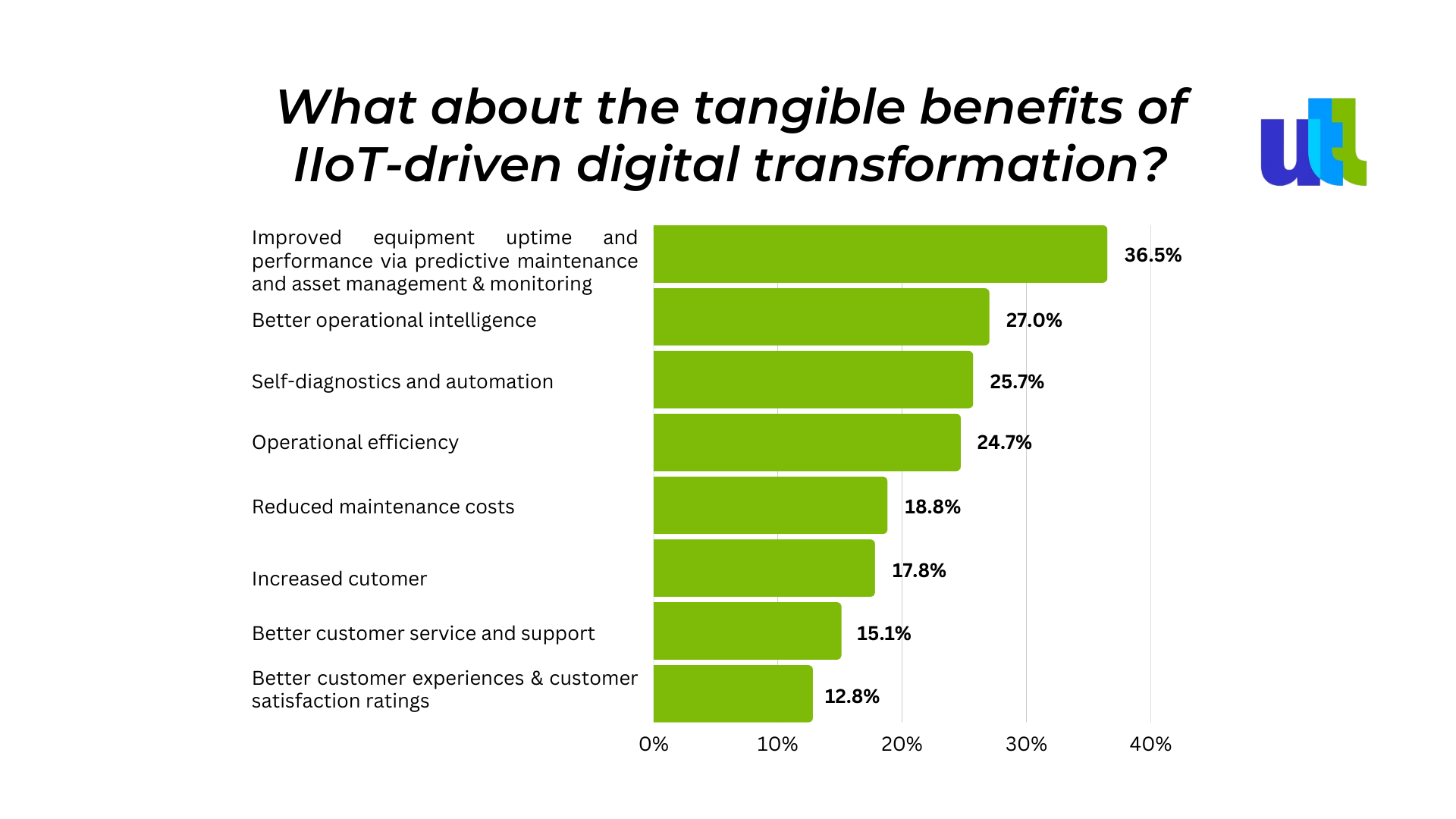

What about the tangible benefits of IIoT-driven digital transformation?

BPI Network carried out an IIoT study, where they surveyed enterprise executives and innovation leaders asking them to name the top benefits of IioT. They got the following results:

All the mentioned improvements are somehow related to one of the two main benefits of IoT in the manufacturing industry: higher transparency and faster communication. Sensors and devices ensure better monitoring of operations, better KPI adherence, and enhanced supply chain control.

The adoption of IIoT in Manufacturing

Industrial IoT employs a network of sensors, collects critical production data, and uses cloud software to turn the gathered data into valuable insights. Its main adoption drivers include:

- Shorter time-to-market.

Implementing faster and more efficient manufacturing and supply chain operations result in reducing product cycle time. In some cases, the time-to-market can decrease from 21 days to 6 hours.

- Significant cost reduction.

IIoT helps to reduce operational costs and creates new sources of revenue due to optimized asset and inventory management, shorter search times, reduced machine downtime, and more efficient energy use.

Smart, connected products allow to shift from selling products to selling experiences.

- Higher customization

To start the mass customization process, companies need a dramatic increase in the variety of produced SKUs. This causes inventory to go up and become more diverse. Manufacturing operations become more complex as well (the production of 10 items of SKU X can be immediately followed by the production of 5 items of SKU Y). IIoT becomes a source of real-time data required for high-quality forecasting, shop floor scheduling, and routing, and, thus, facilitates mass customization.

- New safety levels

Nowadays, put more focus on creating safer workplaces. For example, with the help of wearable devices, it is possible to constantly monitor workers’ health state and warn them about risky activities that can lead to injuries. Furthermore, the Industrial Internet of Things addresses safety problems in potentially hazardous environments (for instance, in the oil and gas industry, IIoT is applied to monitor gas leakages).

Use cases of Industrial IoT in manufacturing

- The maintenance of predictive equipment

IoT sensors collect data on a wide range of parameters (such as health and performance: temperature, pressure, vibration frequency, etc.). Once the real-time data from multiple sensors is collected, it is transmitted to the cloud, where sensor readings are combined with metadata, equipment usage history, and data from ERP, maintenance systems, and more. The data is analyzed and can be shown to workers on a preferred dashboard or in a mobile app.

- Smart factories

Also known as connected factories, smart factories use the Internet of Things technology to optimize the whole manufacturing process rather than certain tasks. Sensors, smart devices, and cloud-based data analytics systems work together to support smooth factory operation and bring new levels of efficiency.

- Industrial asset management

Industrial IoT systems for asset management typically include not expensive and easy-to-manage RFID transponders or Bluetooth trackers to streamline warehouse management, inventory management, supply replenishment, and other activities.

- Workplace safety assurance

Wearable worker communication gadgets monitor strict compliance with safety regulations and send out safety alerts in potentially hazardous scenarios. The data gathered by the sensors is relayed to the cloud where it is analyzed against contextual data to detect unusual behavior patterns (such as unusual heart rates).

2023 trends for IoT in manufacturing

Below we have gathered some of the latest 2023 trends:

1. Location tracking. Real-time location systems (RTLS) are based on wireless technologies, such as Wi-Fi, BLE beacons, UWB, and RFID.

2. 5G connectivity. 5G is an additional boost for IoT-enabled manufacturing solutions. It enables tighter control in critical real-time applications, such as remote surgeries.

3. Automated Quality Assurance. AI-driven visual inspection solutions would not be possible without IoT sensors and cameras to give eyes and ears to the decision-making process.

4. Edge computing. The Edge AI concept allows AI computation to be done near the user at the edge of the IoT network, instead of a cloud. That helps bring real-time intelligence to industrial processes, increase privacy, and enhance cybersecurity, at the same time reducing costs and securing persistent improvement of the manufacturing processes.

5. Energy optimization. By using IIoT energy optimization sensors to monitor the electrical status and usage of devices and machines in a factory, operators can fine-tune the process and automatically optimize energy usage by various devices.

Having an IoT development team that understands your needs and vision for success is paramount for achieving your goals. Furthermore, it will help you avoid all the common pitfalls while implementing your industrial IoT solution.

From industrial technologies to industrial maintenance and parts, we have the breadth and depth to be your technology partner and source for improved uptime and productivity. Contact Utah Tech Labs for more information.

Conclusions

Stronger demand for customization, increasing customer expectations, and the complexity of the global supply chain – these and other challenges encourage manufacturers to search for new, more advanced ways to remain competitive. The Industrial Internet of Things (IIoT) is the solution for digital transformation in manufacturing. According to Grand View Research, the global IIoT market size will reach $949 billion by 2025. This means getting smarter is no longer optional for manufacturers that want to succeed in the Digital Transformation in 2023.

For free consultation on IoT in the manufacturing industry click here.

----------------------------------------------------------------------------------------------

View the full presentation:

WRITTEN BY

Sofia Kutko

2023-07-06